- Home page

- Services

- Welding technology

- Passion for complex welded assemblies

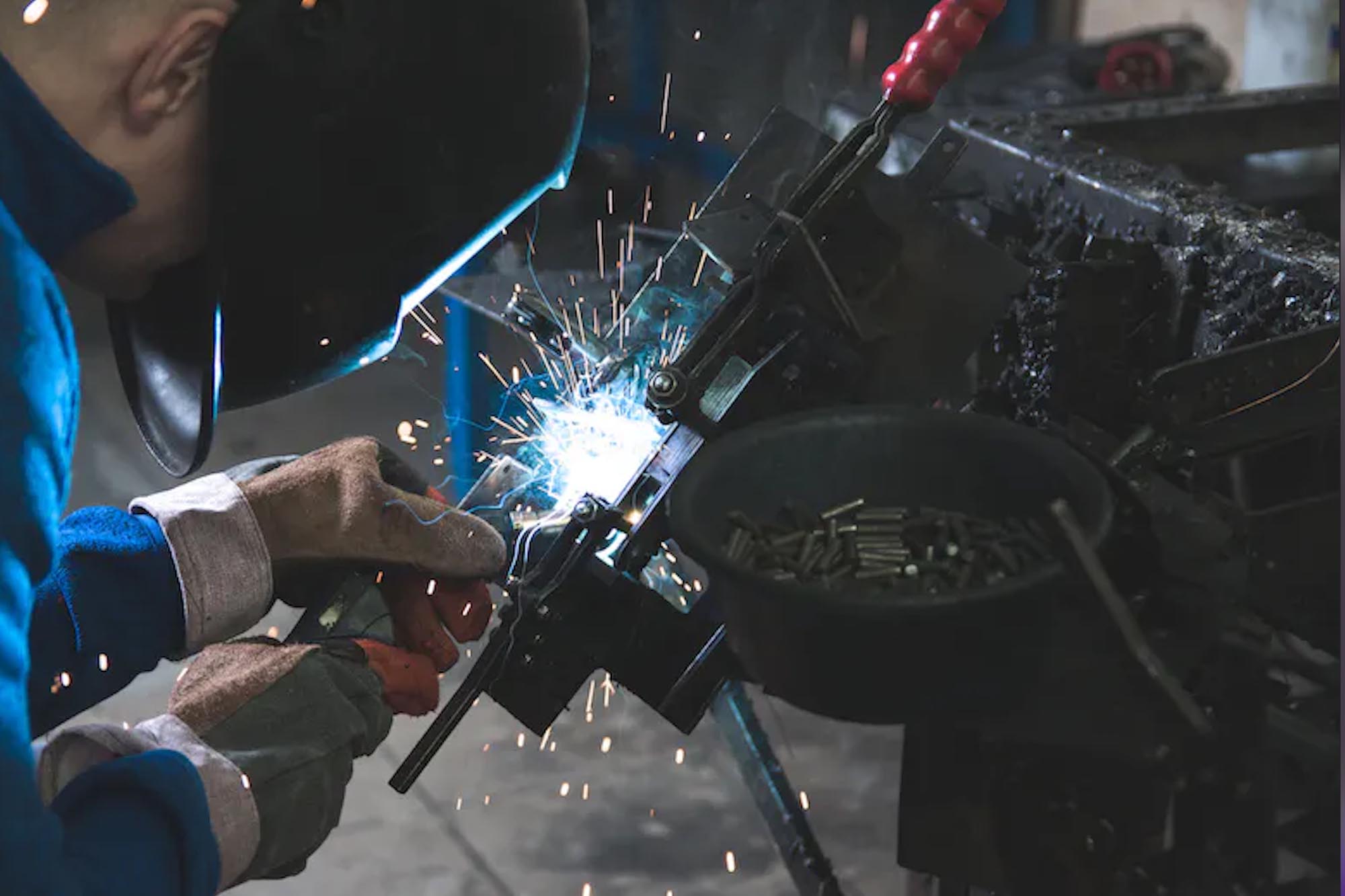

Welding technology

We use high-tech joining processes in the field of welding technology. With the help of state-of-the-art welding robots (MAG/MIG), we are able to produce even complex welded assemblies in series with a high degree of repeat accuracy. Machining sizes up to a diameter of max. 1400 x 5000 mm and a weight of one ton are possible.

We produce parts according to your individual design ideas and technical requirements in our separate stainless steel production facility.

These high-quality components are produced using proven craftsmanship by our certified specialists in the field of TIG welding technology.

Thanks to our wide range of options in welding technology, we can produce a broad spectrum of ready-to-install assemblies according to your requirements.

All welding work is always carried out with the highest quality and reliability by our qualified and certified colleagues.

For us, thinking in µ means precision, passion and the pursuit of unique quality. It is our promise to you!

- Our motto

GDH – powerful in connecting!

We bring together,

what belongs together.

- Overview

Technical data

Regularly trained and certified specialists enable the production of high-quality and complex welded assemblies with high precision.

- Robot welding (MAG/MIG) up to Ø 1400 x 5000 mm

- Weight max. 1 t

- Manual TIG welding

- Manual welding MAG/MIG

Possible materials

- Sheet metal, low-alloy construction and structural steels

- High-alloy steels

- Heat-resistant steels

- Aluminum alloys

- Your advantage