- Home page

- Services

- Measurement technology

- Passion for maximum precision

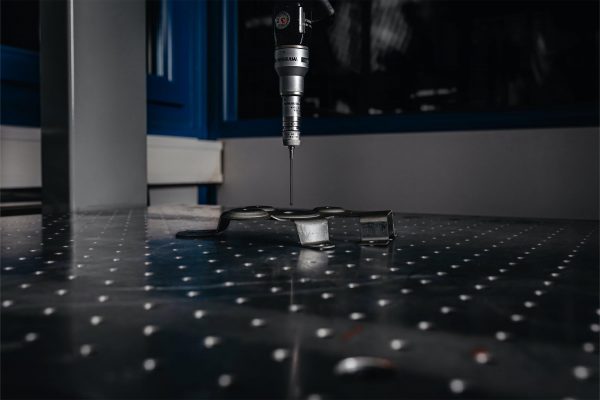

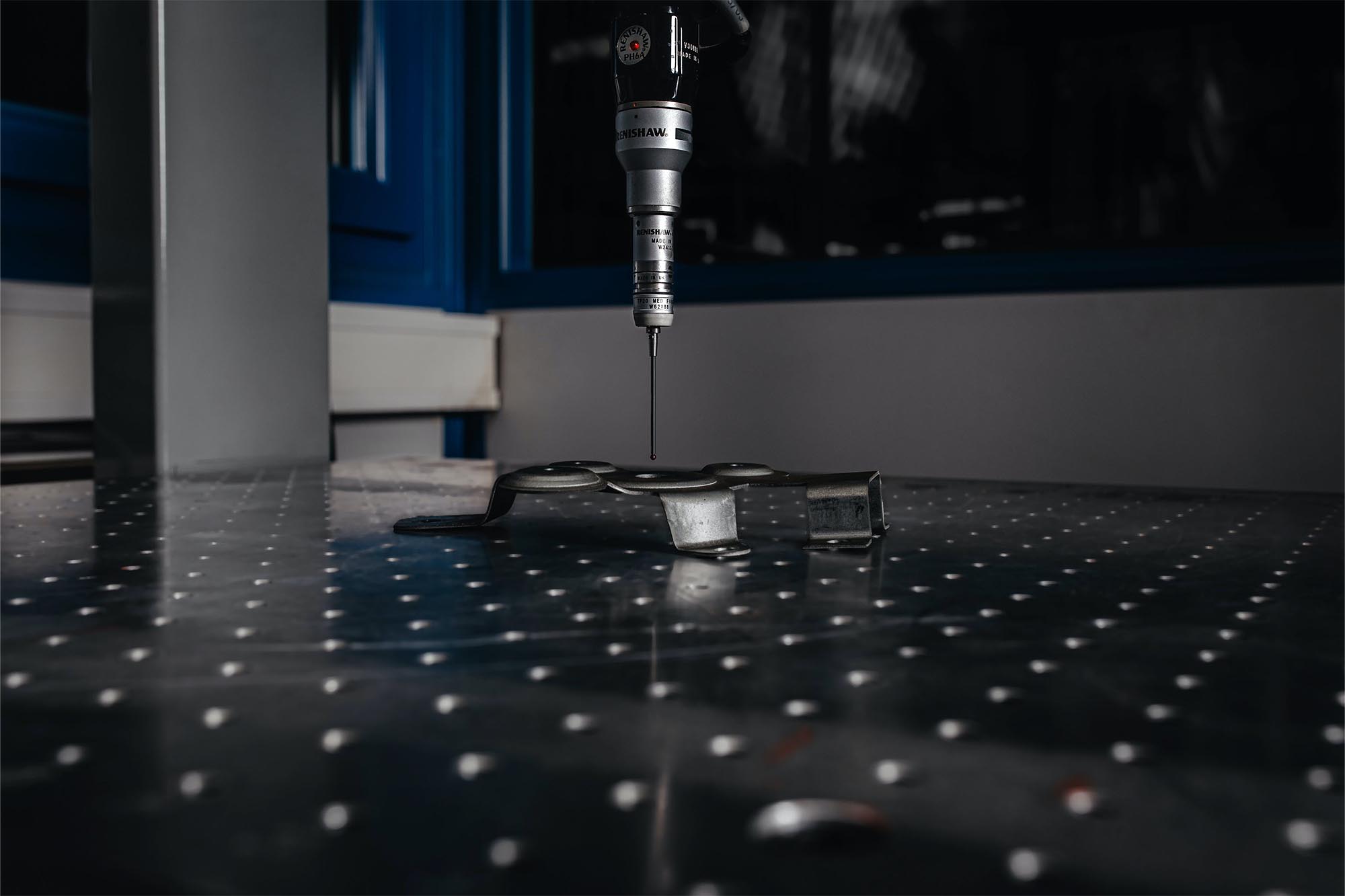

Measurement technology

From part inspection with our coordinate measuring machines to laser measurement, we have numerous state-of-the-art technologies in metrology. Thanks to our measurement techniques and our quality management system, we can offer you high quality from prototype to series production and guarantee consistent reproducibility and, if required, seamless batch traceability.

For tool production, we manufacture the active parts of your tools exactly according to your samples using scanning processes and reverse engineering, even without CAD data. On request, we will be happy to send you a measured initial sample including an initial sample inspection report.

We are very familiar with the requirements of the DIN EN ISO 9001:2015 quality standard. By creating and constantly optimizing inspection plans, regular internal and external audits, constant monitoring of the production process and the dimensional accuracy of the manufactured parts, we guarantee a consistent quality standard.

Inspection documentation in accordance with VDA is possible by arrangement. This makes us the ideal partner for high-precision measurements, which are essential for seamless process and quality monitoring from development through production to delivery.

For us, thinking in µ means precision, passion and the pursuit of unique quality. It is not only our motto, but also our promise to you!

- Our motto

GDH – measure, scan, reproduce.

Guaranteed and

certified quality

- Overview

Technical data

- Consistent quality standard through the creation of inspection plans, regular internal audits and comprehensive control measures

- If required, our precise measuring technology enables production according to existing samples (without corresponding CAD data)

- Certification according to DIN EN ISO 9001:2015

Measurement methods used

- Tactile measuring methods

- Optical measurement methods

- 2D/3D measurement methods

- Scanning methods

- Check against dataset

- Coating thickness measurement

- Climatic measuring rooms

- X-ray fluorescence analysis

- Measurement of residual magnetism

- Measurement of surface tension

- Your advantage