- Passion for modern machining technology

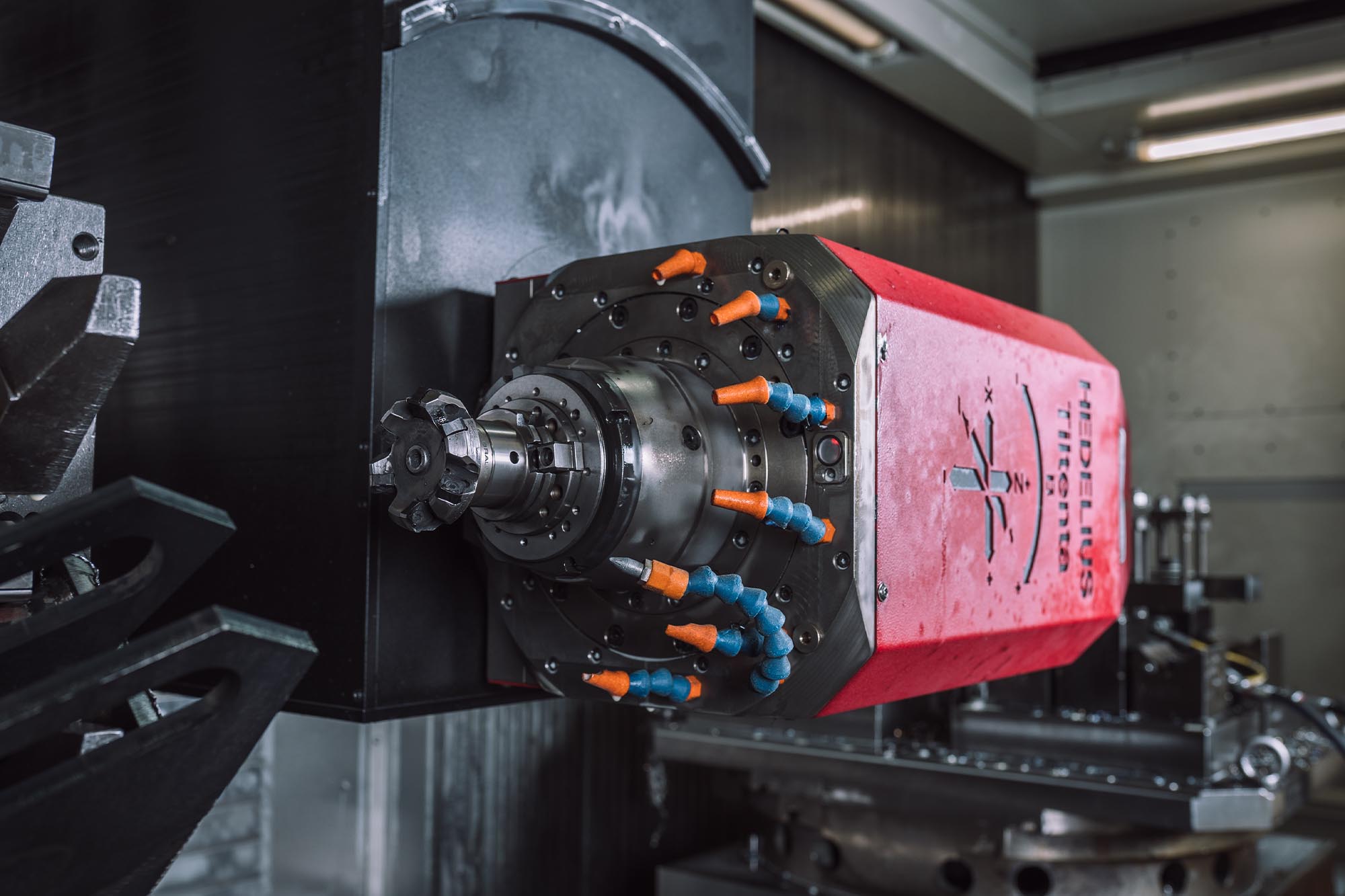

Mechanical processing

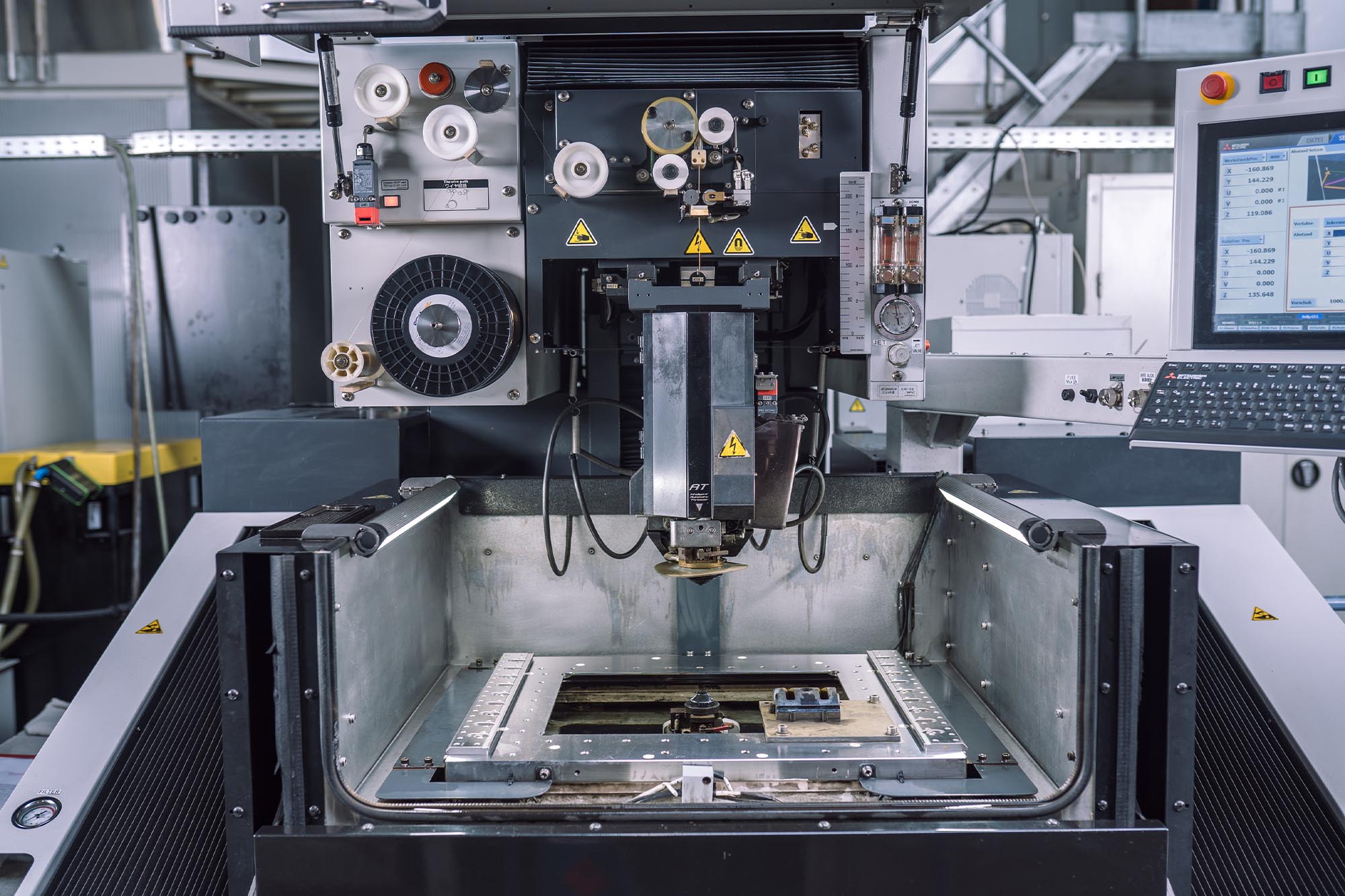

Our capabilities in the field of machining technology allows us to process different shapes and contours. Using milling, turning, sawing, grinding and wire erosion technologies, we manufacture metallic workpieces from single part production to series production and meet the highest standards of quality and delivery reliability. We call this thinking in µ.

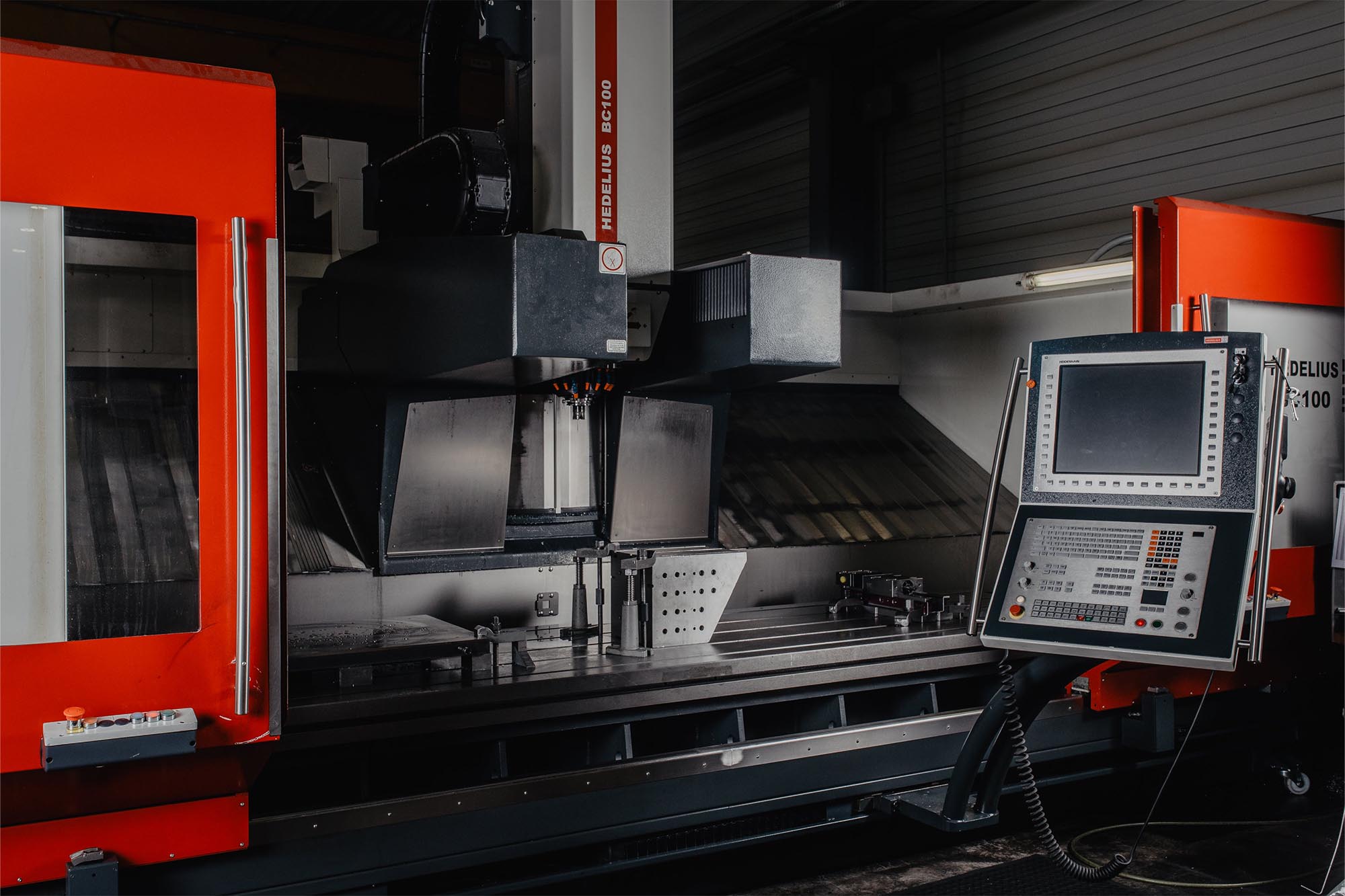

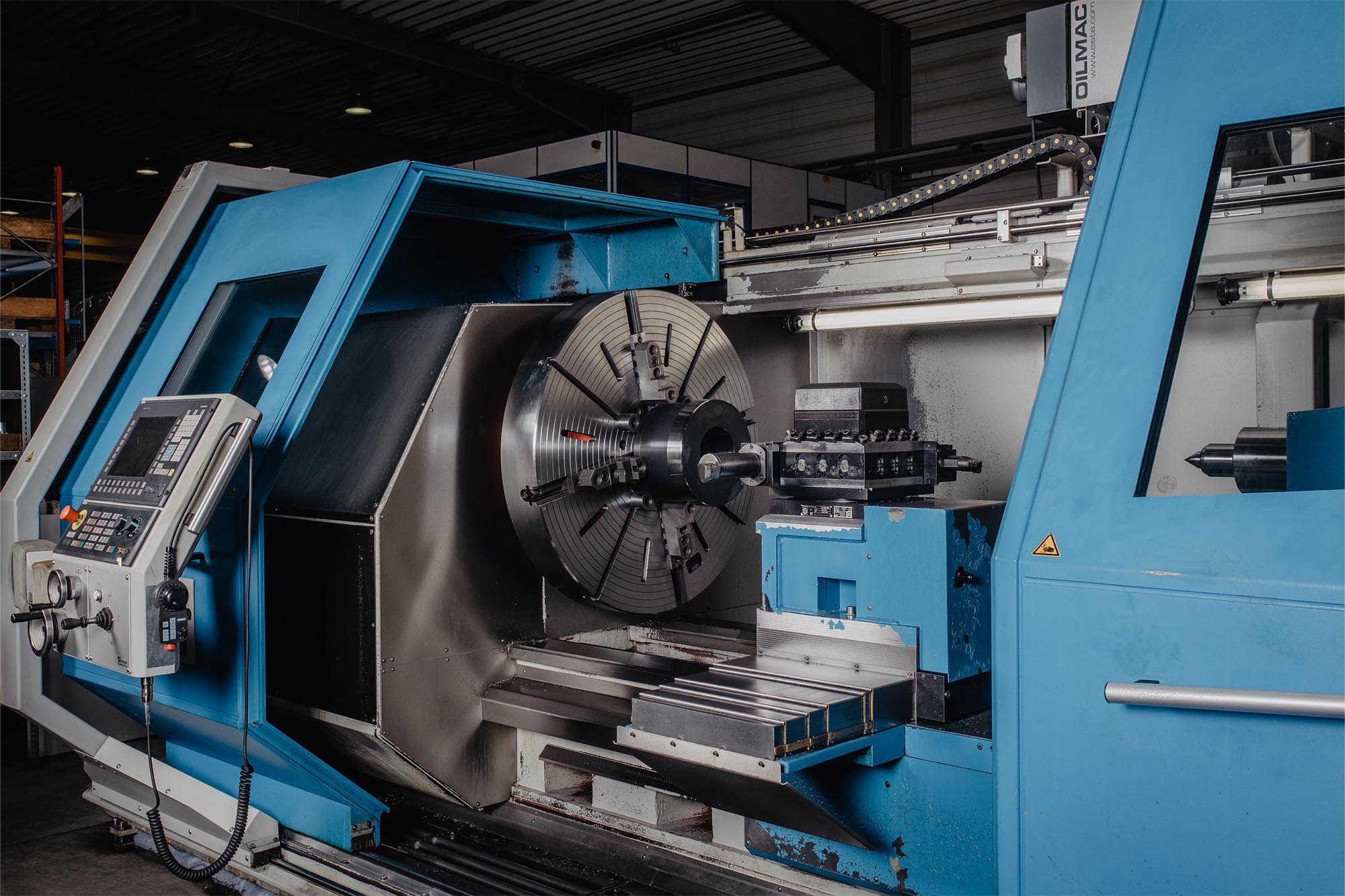

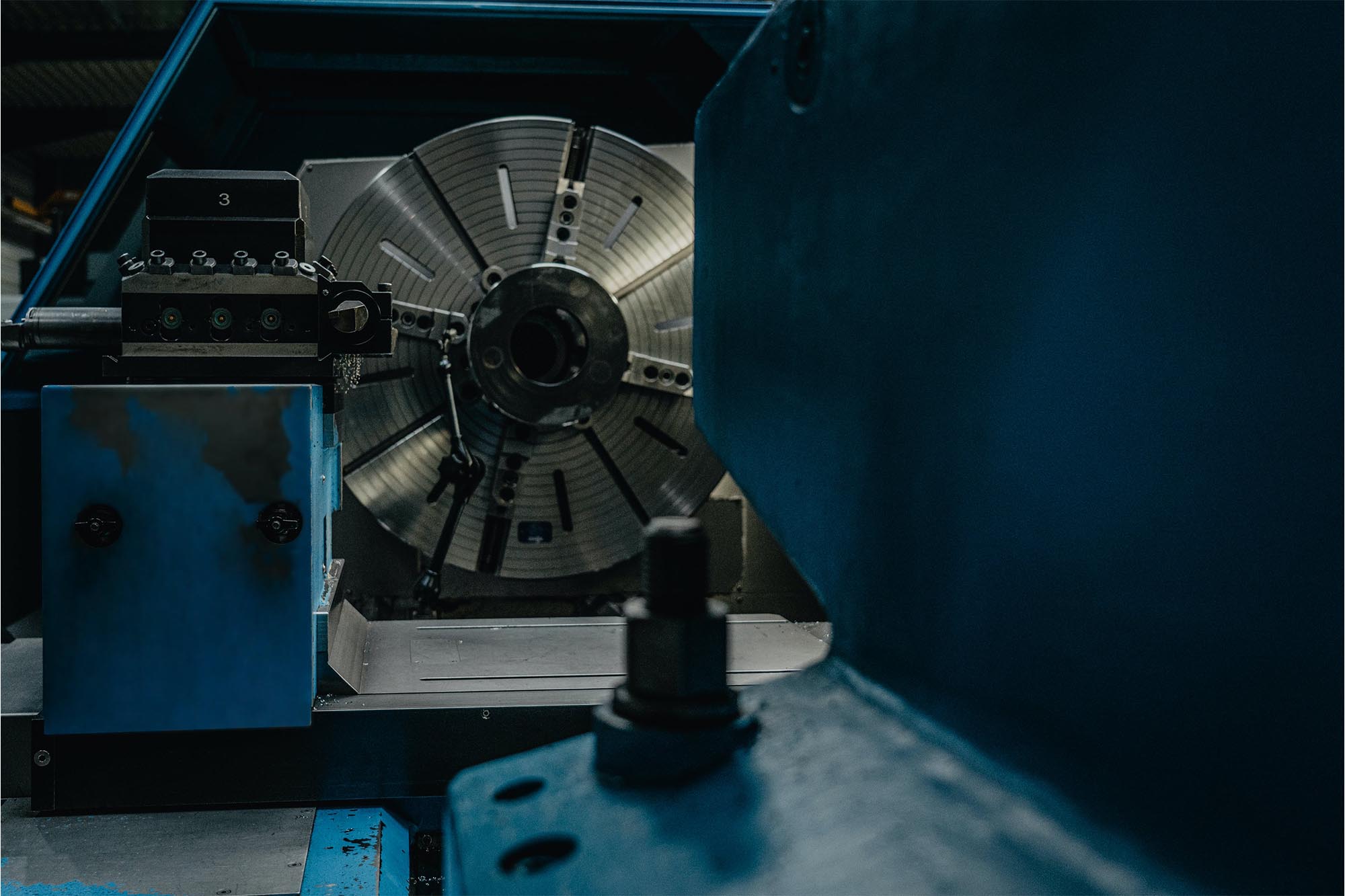

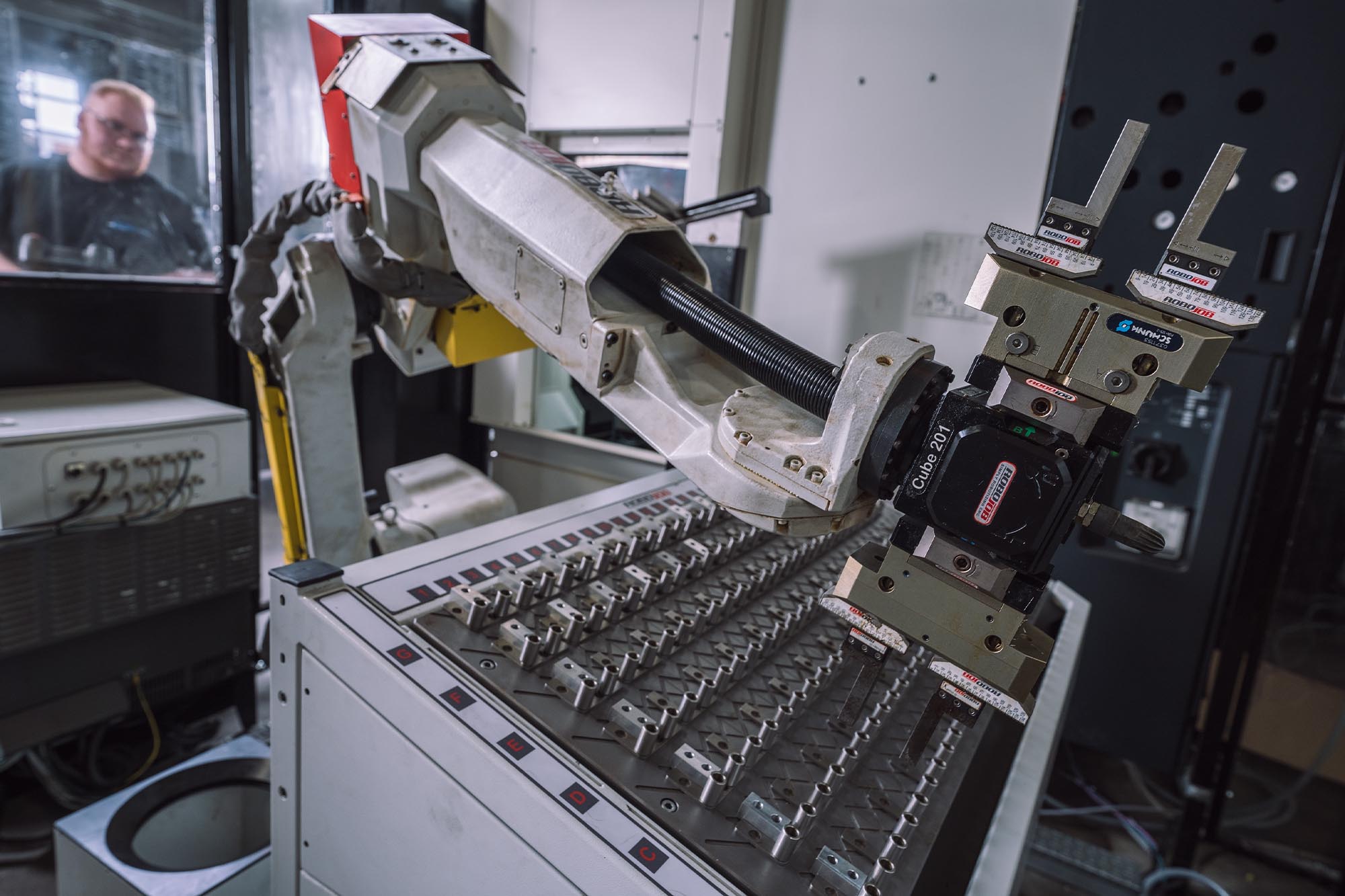

With the help of CNC-controlled milling and turning machines, we manufacture your parts with a high level of production reliability, quality and productivity. This means that complex workpieces can also be processed in series with high repeat accuracy.

Wire-cut EDM technology makes it possible to produce extremely intricate contours with a small cutting width and maximum dimensional accuracy. Processing is possible for any electrically conductive material.

By combining our diverse manufacturing processes and our expertise, we offer short coordination and transportation routes as well as high flexibility and fast response times.

This makes us your contact for complex machining requirements and projects in which quality, passion and speed of implementation are important requirements.

Thinking in µ is not only our motto, it is also our

promise to you!

- Our motto

GDH – we remove,

what is excessive!

- Overview

Technical data

We process the following materials:

- Structural steels

- Low and high-alloy steels (stainless steels)

- Aluminum

- Brass

- Copper

- Plastics

Machining in figures

- Milling 3 axes up to 4600 x 900 x 800 mm

(table size 5000 x 900 mm) - Milling 4 axes up to 4600 x 900 x 800 mm

(table size 5000 x 900 mm) - Milling 5 axes up to Ø 840 x 500 mm (max. 600 kg)

- Turning up to Ø 1200 x 2000 mm

- Automated turning with bar loader up to Ø 80 mm with counter spindle

- parallel surface grinding up to 700 x 1000 mm

- Wire EDM up to 400 x 600 x 300 mm

(table size 900 x 800 mm)

- Your advantage